- #HOW TO SET THE CNC USB CONTROLLER SOFTWARE HOW TO#

- #HOW TO SET THE CNC USB CONTROLLER SOFTWARE PC#

- #HOW TO SET THE CNC USB CONTROLLER SOFTWARE SERIES#

A circle drawn in Inkscape can be used to create a hole in your material. This helps to avoid surprises later, such as running over the edge of your material. The first thing I normally do is open the “File/Document Properties” dialog and set the units to mm and the page size to the approximate size of the area I intend to cut. This way you can move through 1mm thick material in multiple passes and keep a close eye on things as you go through the process the first time.Īn example workflow for 2.5D milling starts with using Inkscape to lay out where you want to make your cuts. An introductory approach to doing 2.5D is to cut out a 2D pattern and then home the X, Y, Z to have the Z axis 0.1mm lower and recut the same design. A good place to start is with engraving and 2.5D milling.

#HOW TO SET THE CNC USB CONTROLLER SOFTWARE HOW TO#

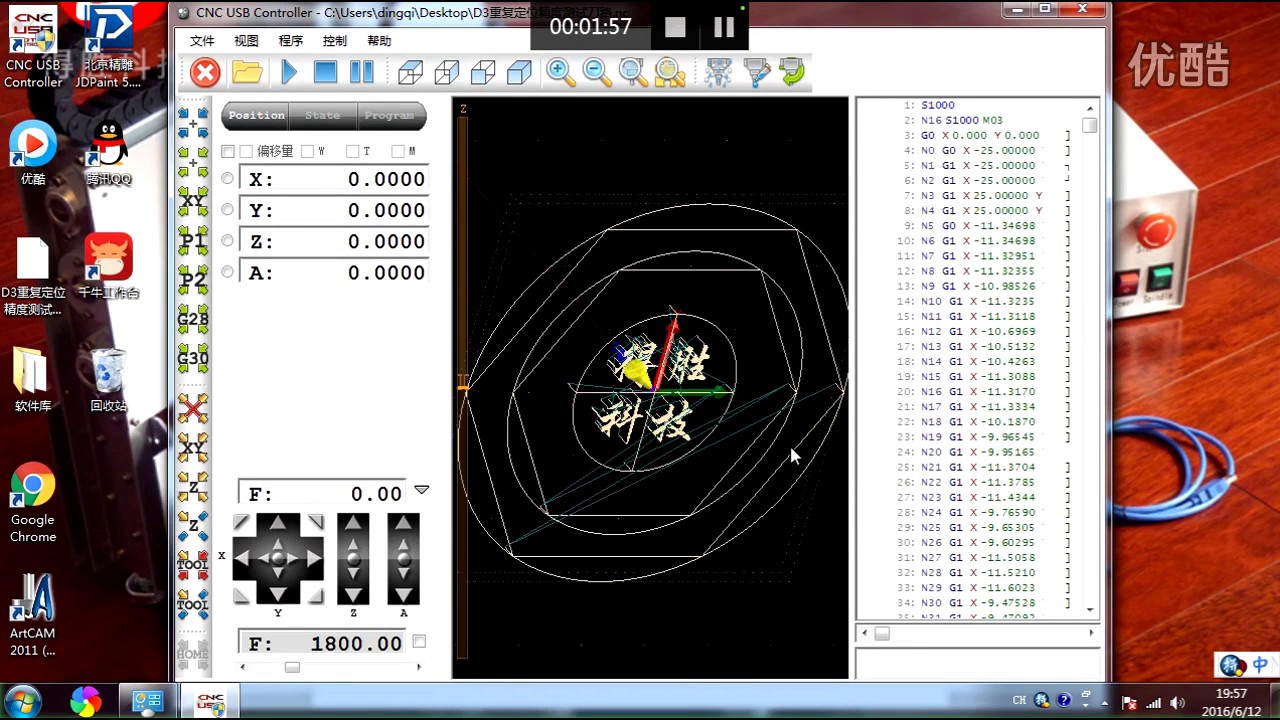

It can be a little intimidating working out how to create G-code files and the process to start creating things with a CNC. The cutting spindle is on the left under the control of the original board and power supply. The Ethernet cable is on the top left, and the DC power is connected to the left side of the board. The three stepper motors are connected to the X, Y, and Z connectors along the top of the board. Because the Smoothieboard is also open hardware, you can find many suppliers of compatible boards depending on your needs.įigure 2 shows a Smoothieboard compatible board.

#HOW TO SET THE CNC USB CONTROLLER SOFTWARE PC#

Using the Smoothieboard, you do not have to bring a PC close to the CNC to use it, and you can interact with the Smoothieboard from any machine over the network. The Smoothieboard has an Ethernet port and a 100Mhz microcontroller to read your G-code and tell the stepper motors on the CNC machine where to move to cut out your design. If you are handy with a soldering iron, you might want to replace the controller board that comes with the 3040 with a Smoothieboard. The expectation is that you will have a dedicated PC with a parallel port and use something like LinuxCNC to control the CNC. One issue here is that true parallel ports are difficult to find on modern PCs.

The 3040 number indicates the size of the bed that might be serviced by the cutting tool (30×40 cm), although you are likely to get slightly less than that in each dimension.Ī big disadvantage of the 3040 CNC is that, by default, it is controlled over a parallel port. Options range from the Shapeoko kit and X-Carve through to the “3040 CNC” machines from China (Figure 1), which can be found on eBay. Hobby CNC machines are available for around a thousand dollars or less. The cutting distinction is useful because the CNC can move faster if it knows it is not meant to be cutting anything when moving the position of the cutter. A G-code file might tell the machine to move to an X=100 and Y=0 position from the current location, while not “cutting.” The CNC might interpret that command by accelerating the cutting head up to a maximum speed and then decelerating as it gets closer to the destination. It also controls whether the head should be turned on and off and other things. You control a CNC machine using a G-code file, which has commands that tell the machine where to move the cutting head. The CNC can also engrave what the button does right next to the hole that it has created. This is a big advantage if you want to create some button holes in a panel. Hobby CNC machines look a bit like 3D printers, with the ability to move in at least X, Y, and Z dimensions, but instead of extruding plastic to create things, they have many cutting bits that let you slice away material to expose the final object you want.Ī CNC can remove just a small amount of material, create holes right through something, or use a cutting head to engrave something on a panel. Instead of measuring this out and using a drill press, you can attach your control panel to the cutting area of a CNC and have the machine create it for you. At the simpler end of the spectrum, you might like to create a control panel with buttons at set distances from each other, or perhaps you also want a square hole for a display. The object can be as simple as a few holes in a panel for lights or as complex as a large engine.

#HOW TO SET THE CNC USB CONTROLLER SOFTWARE SERIES#

A Computer Numerical Control ( CNC ) machine interprets a series of commands and creates a physical object for you.

0 kommentar(er)

0 kommentar(er)